Vinyl Printing vs. DTF Printing: A Comparative Overview

In the world of custom apparel and textile printing, choosing the right printing method is crucial for achieving the desired results. Two popular techniques in this space are Vinyl Printing and Direct-to-Film (DTF) Printing. Both have their unique strengths and applications, making them suitable for different needs and projects. Below is a comprehensive comparison of these two methods to help you decide which one is best for your needs.

1. Vinyl Printing

What It Is:

Vinyl printing involves cutting designs out of colored vinyl sheets and then heat pressing them onto garments. This technique is widely used for creating custom t-shirts, sports jerseys, and other promotional items.

Advantages:

- Durability: Vinyl prints are known for their long-lasting quality. They can withstand frequent washing and wear, making them ideal for athletic wear and work uniforms.

- Vibrant Colors: Vinyl sheets come in a wide range of colors, including specialty finishes like glitter, metallic, and reflective. The colors tend to be bright and consistent.

- Sharp Edges: The cutting process allows for clean and precise edges, making it suitable for simple, bold designs like logos or text.

- No Minimum Order: Vinyl printing is cost-effective for small orders, even a single item, as there’s no setup cost involved.

Disadvantages:

- Limited Detail: Vinyl printing is not ideal for highly detailed or intricate designs. Complex images can be difficult to cut and apply.

- Feel of the Print: Vinyl can have a slightly raised, plastic-like feel on the garment, which might not be desirable for all users.

- Time-Consuming for Large Orders: The process of cutting and weeding the vinyl can be labor-intensive, especially for large quantities.

2. Direct-to-Film (DTF) Printing

What It Is:

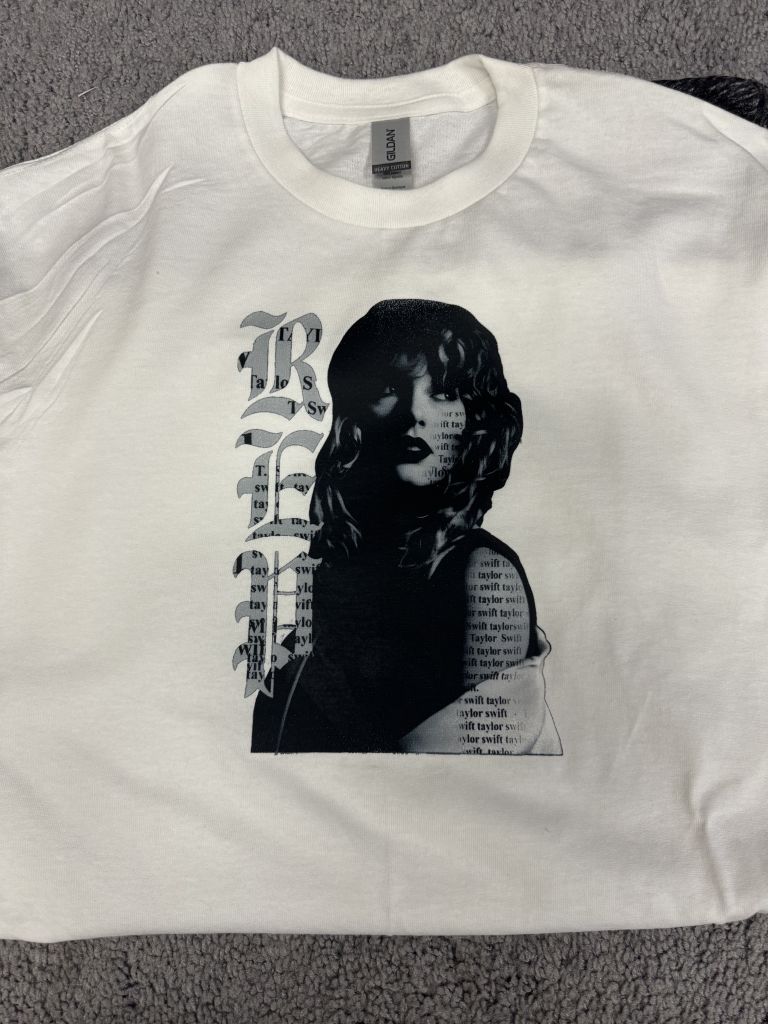

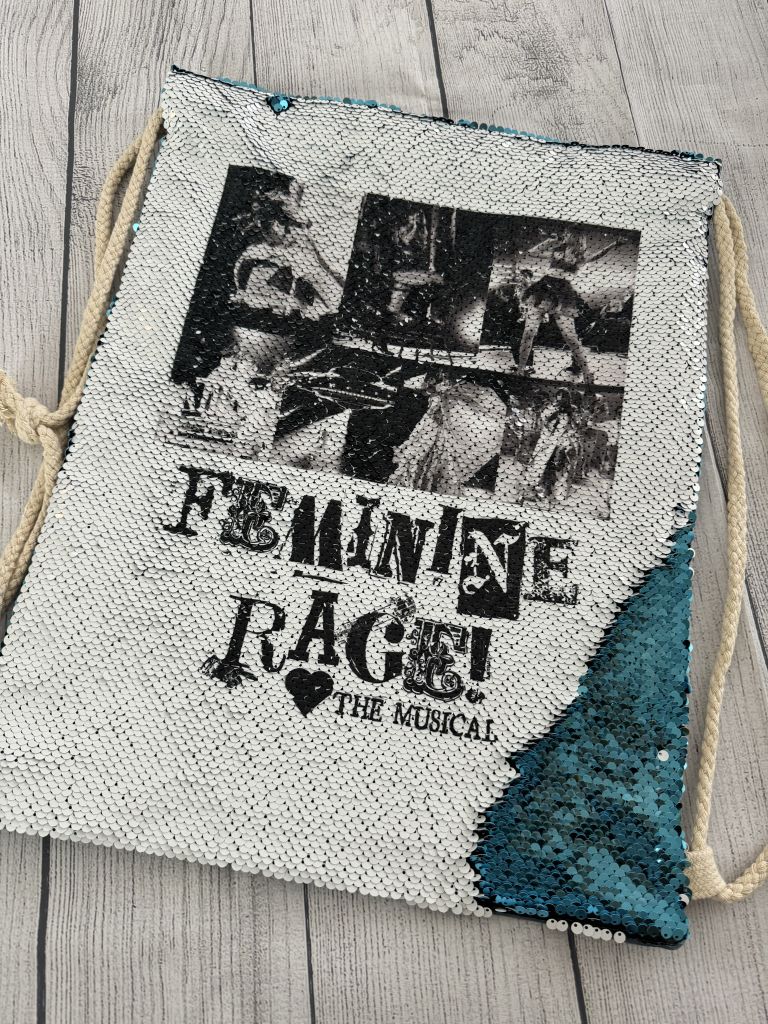

DTF printing is a newer technology where designs are printed onto a special film and then transferred to the fabric using heat. It allows for printing complex, full-color images directly onto garments, similar to Direct-to-Garment (DTG) printing, but with some distinct advantages.

Advantages:

- High Detail and Color Range: DTF printing excels at producing intricate designs with a wide range of colors. It can handle gradients, shading, and photographic images with ease.

- Versatility: DTF printing works on a variety of fabrics, including cotton, polyester, and blends. It can even be applied to non-textile surfaces, offering greater flexibility.

- Soft Hand Feel: The transferred image integrates well with the fabric, resulting in a softer feel compared to vinyl.

- Durability: DTF prints are highly durable and resistant to cracking, fading, and peeling over time.

- Efficient for Large Orders: DTF is ideal for larger batches as it reduces the labor associated with weeding and cutting vinyl.

Disadvantages:

- Initial Setup Cost: DTF printing requires specialized equipment and materials, which can be a barrier for small businesses or hobbyists.

- Maintenance: The printers and heat presses used in DTF require regular maintenance to ensure consistent quality.

- Cost for Small Orders: For small quantities, DTF can be more expensive compared to vinyl, especially when considering the cost of setup and materials.

3. Choosing the Right Method

The choice between vinyl printing and DTF printing ultimately depends on the specific needs of your project:

- Go with Vinyl Printing if: You need durable, simple designs with solid colors, especially for smaller orders or items that will see heavy wear.

- Opt for DTF Printing if: Your project requires detailed, full-color designs, particularly on various fabric types, and you’re working with larger quantities.

Conclusion

Both vinyl printing and DTF printing offer unique advantages and are valuable tools in the custom apparel industry. Understanding their strengths and limitations will help you make an informed decision and ensure your project is a success. Whether you prioritize detail, durability, or cost-effectiveness, there is a printing method that will suit your needs.