Limitations of Vinyl Printing

Vinyl printing, or heat transfer vinyl (HTV) printing, is a popular method for creating custom designs on apparel, signage, and other products. It’s known for its durability, vibrant colors, and versatility across various surfaces. However, vinyl printing is not without its limitations. Being aware of these challenges is crucial for ensuring that your projects meet your expectations and are well-suited to the capabilities of vinyl printing. This page will explore the key limitations of vinyl printing, helping you make informed decisions about when and how to use this printing method.

Material Compatibility and Restrictions

One of the primary limitations of vinyl printing is its compatibility with certain materials. HTV is most effective on fabrics like cotton, polyester, and blends, but it may not adhere well to other materials such as nylon, leather, or heavily textured fabrics. For example, vinyl may have difficulty bonding with fabrics that have a low melting point, like spandex or certain synthetic blends, potentially leading to peeling or poor adhesion. Additionally, vinyl printing is not typically recommended for use on hard surfaces like wood, metal, or glass unless specialized adhesive vinyl is used, which can be more challenging to apply and may require different equipment.

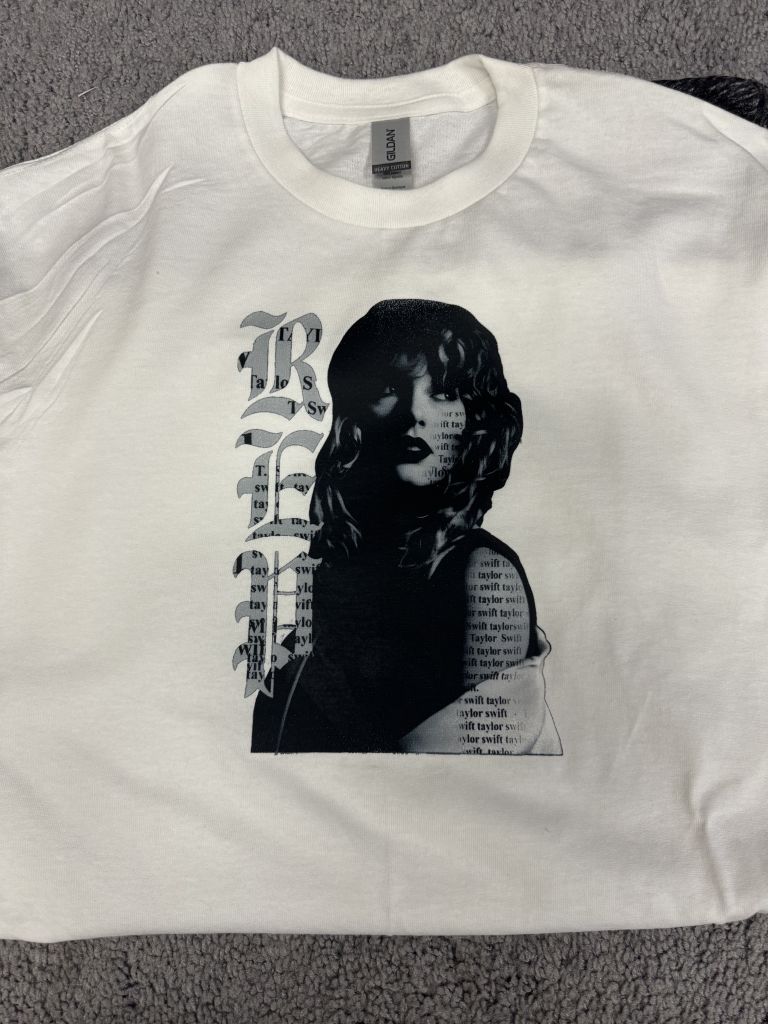

Limited Color Range and Effects

While vinyl printing offers a wide range of colors and finishes, including matte, glossy, metallic, and glitter, it is limited when it comes to producing gradients, shading, or multi-color designs with fine details. Each color in a design requires a separate layer of vinyl, which must be precisely cut and aligned during the application process. This can make it difficult to achieve complex designs with multiple colors or intricate details. Additionally, HTV cannot produce photorealistic images or smooth color transitions, making it less suitable for designs that require high levels of detail or color blending.

Durability and Flexibility Issues

While vinyl prints are generally durable, they can be prone to cracking, peeling, or fading over time, particularly if not applied correctly or if subjected to harsh conditions. The flexibility of vinyl is also limited compared to other printing methods, such as screen printing or sublimation. This can lead to issues with the vinyl print not stretching properly with the fabric, especially on garments that need to accommodate movement, such as activewear. Repeated washing, especially in hot water, and exposure to high heat (e.g., in a dryer) can also accelerate wear and tear, reducing the longevity of the design.

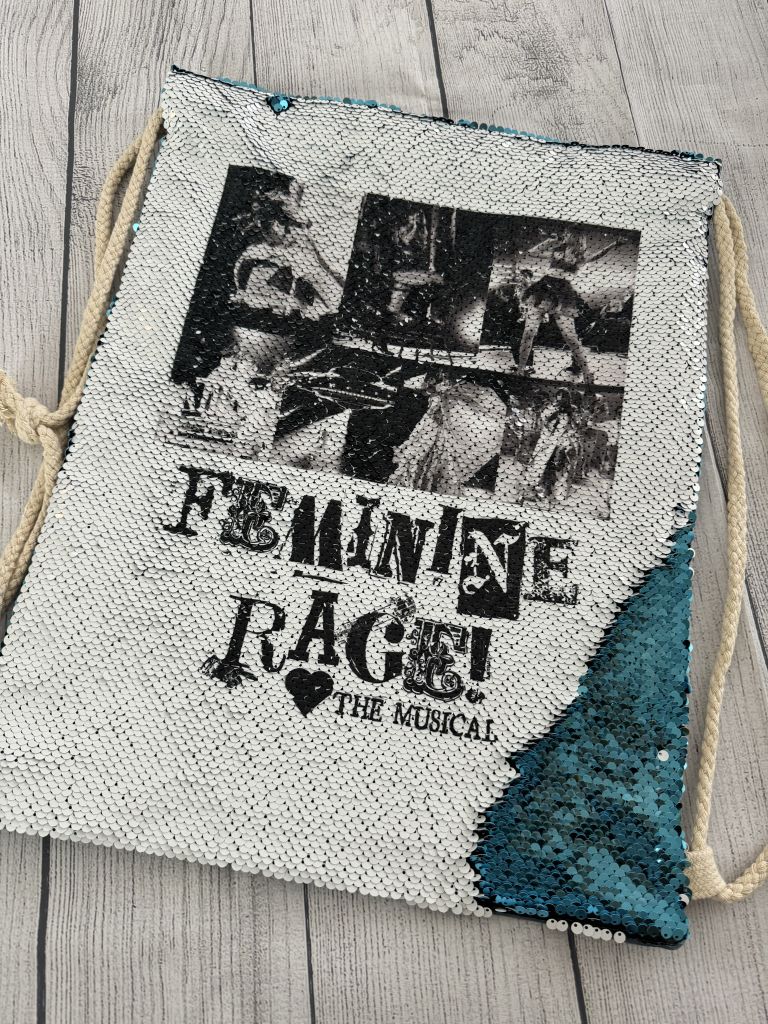

Not Ideal for Large or Complex Designs

Vinyl printing is not the best option for large-scale designs, especially those that cover a significant portion of a garment. Large vinyl prints can feel heavy and may not breathe as well as the fabric itself, which can reduce the comfort of the garment. Additionally, the application of large designs increases the risk of bubbles or creases forming during the transfer process, which can detract from the appearance of the final product. Complex designs that require precise alignment of multiple colors or layers can also be challenging to execute flawlessly with vinyl, leading to potential issues with misalignment or inconsistent results.

Conclusion

Vinyl printing is a versatile and widely used method for creating custom designs, but it has several limitations that should be taken into account. Material compatibility issues, limited color range and design complexity, and durability concerns are all important factors to consider when choosing whether vinyl printing is the right option for your project. By understanding these limitations, you can make informed decisions about how to best achieve your design goals, and explore alternative printing methods if necessary, to ensure that your final product meets your expectations in terms of quality, durability, and sustainability.