Limitations of Sublimation Printing

Sublimation printing is celebrated for its ability to produce vibrant, long-lasting designs on a variety of materials. However, like any printing method, it has its limitations. Understanding these boundaries is essential for achieving the best possible results and ensuring that your projects are well-suited to the capabilities of sublimation printing. This page will explore some of the key limitations of sublimation printing, helping you make informed decisions when choosing the right printing technique for your needs.

Material Restrictions

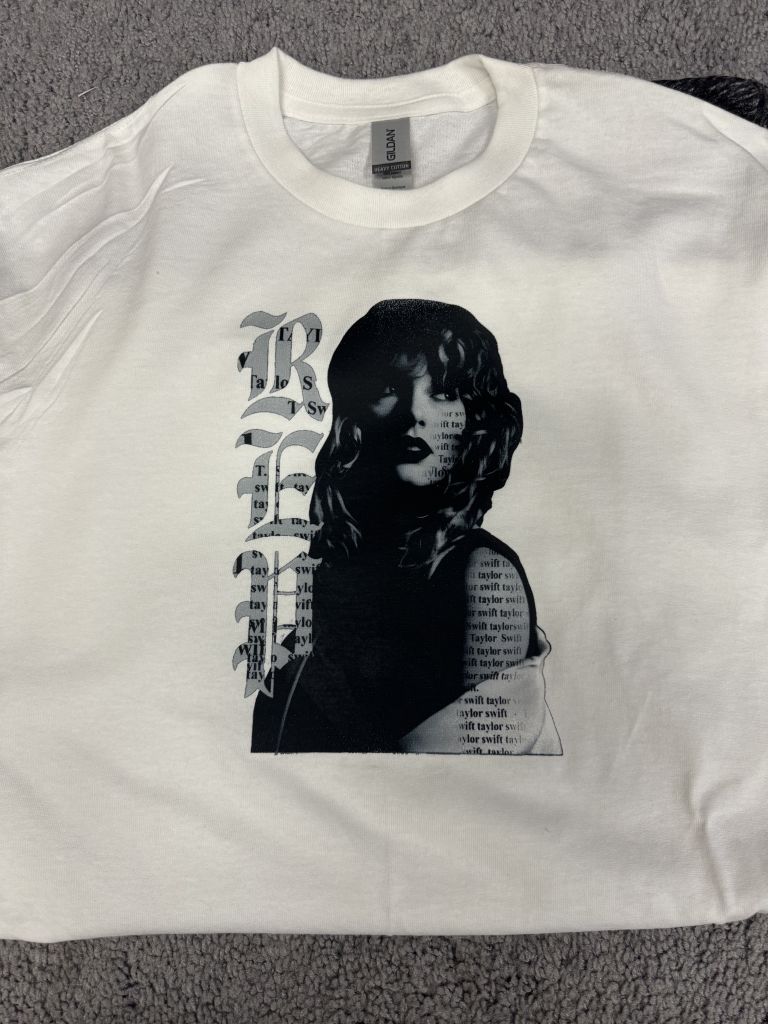

One of the most significant limitations of sublimation printing is its compatibility with materials. Sublimation printing works best on surfaces that have a high polyester content or are coated with a special polymer. This means that natural fabrics like cotton, wool, and silk are not suitable for sublimation printing. While sublimation can be used on polyester blends, the results may not be as vibrant or durable as with 100% polyester materials. Additionally, sublimation printing is not effective on dark-colored fabrics, as the process relies on the dyes bonding with light-colored surfaces to produce vivid results.

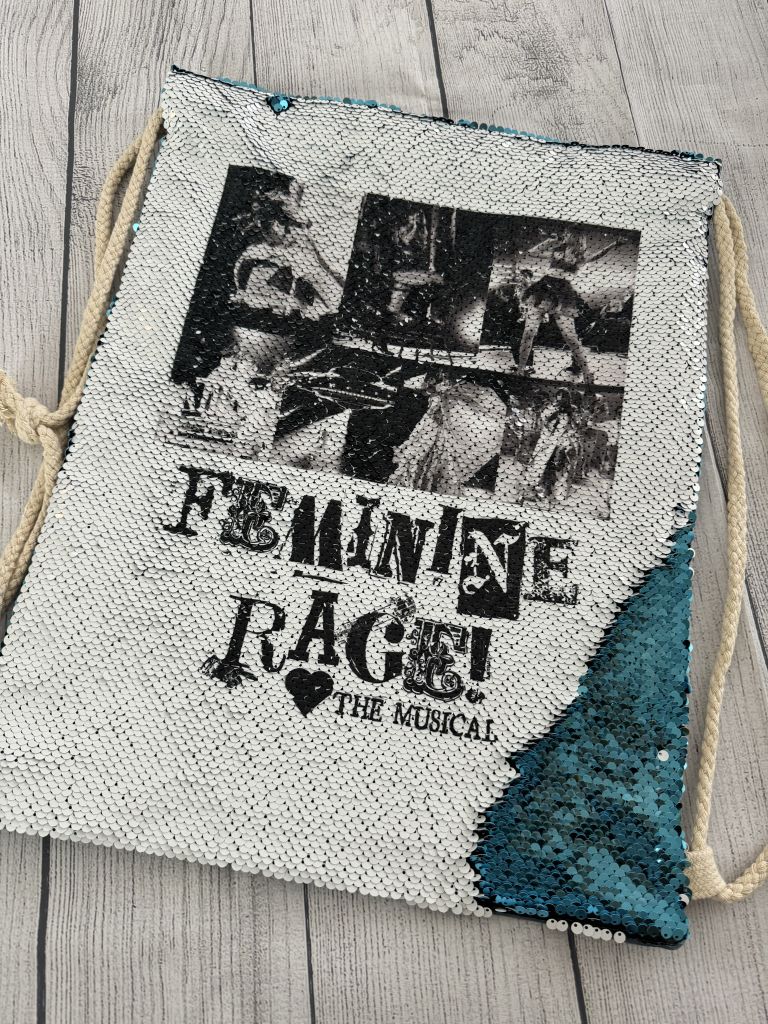

Limited Substrate Options

In addition to fabric restrictions, sublimation printing is limited in terms of the types of substrates it can be used on. While it excels on polyester fabrics, coated ceramics, certain plastics, and specially coated metals, it cannot be used on untreated materials or those that lack a polyester coating. This limits the range of products that can be customized using sublimation, particularly when compared to other printing methods like vinyl or screen printing, which can be applied to a wider variety of materials.

Color Limitations on Dark Backgrounds

Sublimation printing is best suited for light-colored or white surfaces because the dyes used in the process are translucent. When applied to dark-colored backgrounds, the colors may appear muted or distorted, and the design may lose its vibrancy. This limitation makes sublimation less effective for producing prints on black or dark-colored garments and items. To achieve the desired results on dark backgrounds, other printing methods, such as screen printing or direct-to-garment (DTG) printing, may be more appropriate.

Size Constraints

Sublimation printing is typically done using heat presses, which come in various sizes. The size of the heat press dictates the maximum size of the print that can be transferred in one pass. This means that for large designs, particularly those exceeding the dimensions of the heat press, multiple transfers may be necessary. This can lead to potential alignment issues, making it challenging to produce large, seamless prints. For projects requiring oversized designs, alternative printing methods or specialized equipment may be needed.

Conclusion

While sublimation printing offers many advantages, such as vibrant colors and durability, it’s essential to be aware of its limitations. Material and substrate restrictions, color challenges on dark backgrounds, and size constraints are all factors to consider when deciding whether sublimation printing is the right choice for your project. By understanding these limitations, you can better assess your needs and explore alternative printing methods if necessary, ensuring that your final product meets your expectations.