Limitations of DTF Printing

Direct-to-Film (DTF) printing has gained popularity for its ability to produce vibrant, detailed designs on a wide variety of fabrics. While this innovative technique offers many advantages, it also has its limitations. Understanding these challenges is crucial for optimizing your printing projects and ensuring that DTF printing is the right choice for your specific needs. This page will explore the key limitations of DTF printing, providing insights to help you make informed decisions.

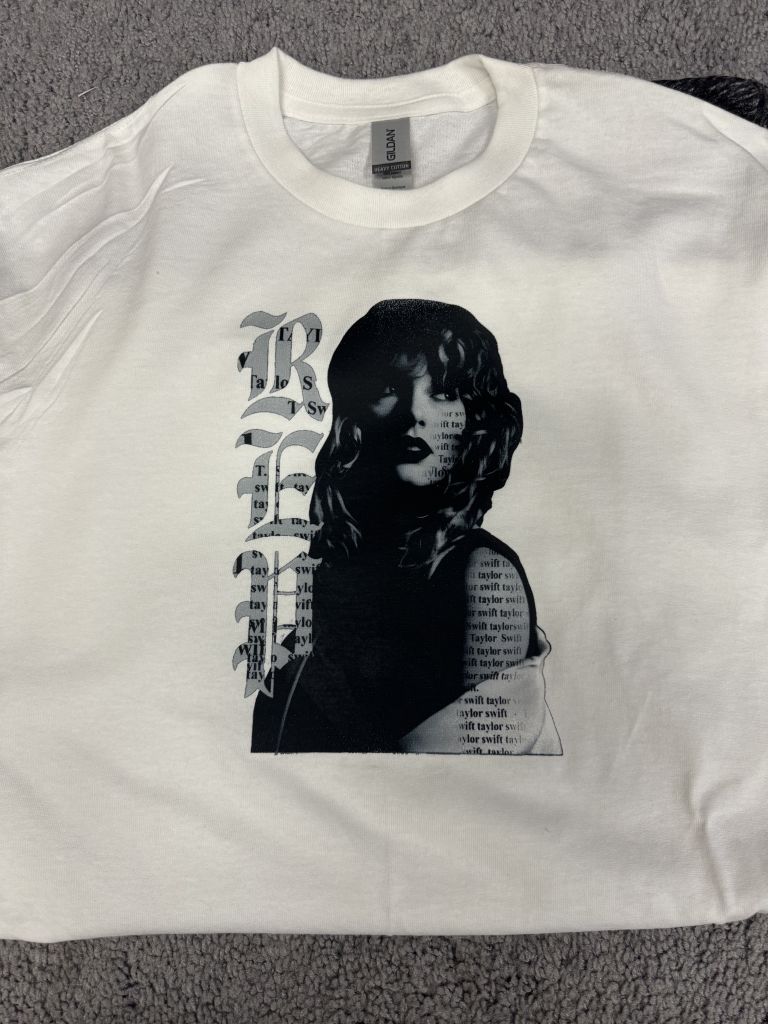

Adhesion Issues on Certain Fabrics

One of the primary limitations of DTF printing is its variability in adhesion quality on different fabrics. While DTF printing works well on cotton, polyester, and blends, it may struggle to adhere properly to fabrics with low melting points, such as nylon or spandex. In some cases, the adhesive used in the DTF process may not bond as effectively with these materials, leading to issues with durability and longevity. Additionally, fabrics with a heavy texture or a loose weave may present challenges in achieving a smooth, consistent print.

Prone to Cracking and Peeling

Although DTF prints are generally durable, they are more susceptible to cracking and peeling compared to other methods like sublimation or screen printing. This is especially true if the garment is frequently washed or subjected to rough wear. The layer of adhesive film that bonds the ink to the fabric can become less flexible over time, leading to cracks in the design. To minimize this risk, it’s essential to follow specific care instructions, such as washing the garments inside out in cold water and avoiding high heat in the dryer. However, these care requirements may not always be practical for all users.

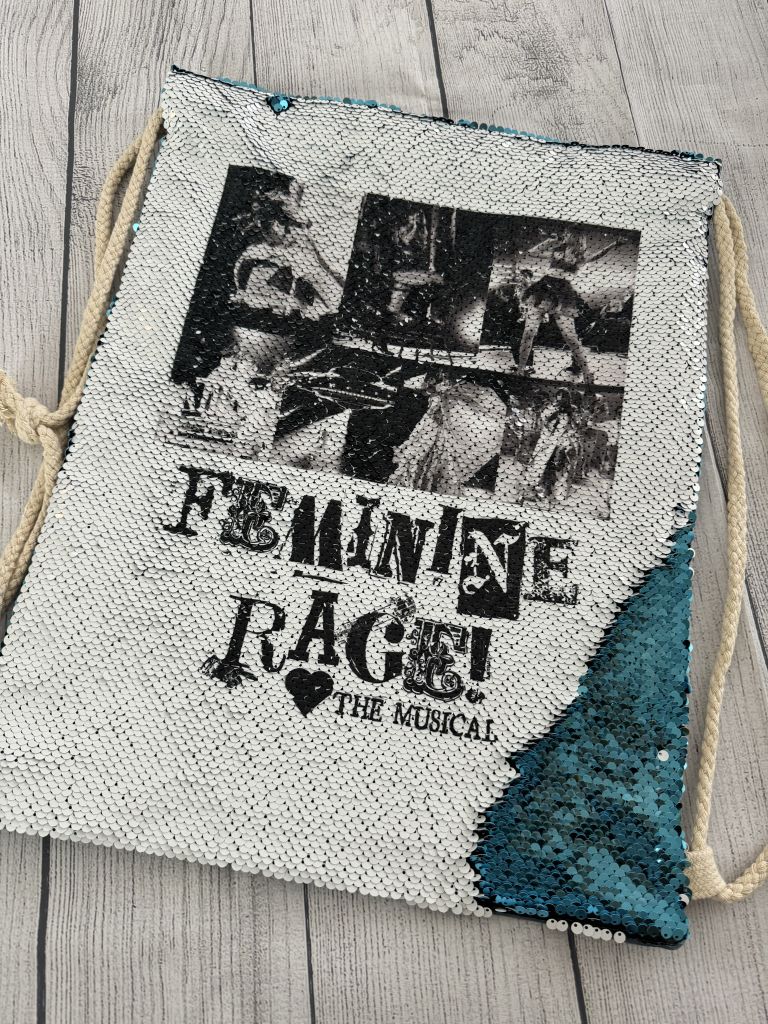

Limited Color Vibrancy on Dark Fabrics

DTF printing allows for vibrant colors on a variety of fabric types, but achieving the same level of vibrancy on dark fabrics can be challenging. The white underbase layer used in DTF printing helps to enhance color brightness on dark materials, but it can sometimes result in a slightly muted or less vibrant finish compared to lighter fabrics. In some cases, additional layers of ink may be required to achieve the desired color intensity, which can increase production time and costs.

Complexity in Multi-Color and Gradient Designs

While DTF printing is capable of producing intricate designs with multiple colors, it can struggle with complex gradients and color transitions. The technology relies on a precise layering process, and maintaining smooth transitions between colors, especially in highly detailed designs, can be challenging. The result may not be as seamless or sharp as other printing methods, such as direct-to-garment (DTG) printing, which excels in handling complex gradients.

Conclusion

DTF printing is a powerful and versatile method for creating custom apparel, but it comes with its own set of limitations. Adhesion issues on certain fabrics, potential for cracking and peeling, challenges with color vibrancy on dark fabrics, and the complexity of handling multi-color designs are important considerations. By understanding these limitations, you can make informed decisions and explore alternative printing methods when necessary to achieve the best results for your custom designs.