DTF Printing vs. Sublimation Printing: A Detailed Comparison

In the custom apparel and merchandise printing industry, choosing the right printing technique is key to achieving the desired outcome. Two popular methods that are often compared are Direct-to-Film (DTF) Printing and Sublimation Printing. Each technique has its own strengths, limitations, and ideal use cases. Below is a detailed comparison to help you determine which method is best for your specific needs.

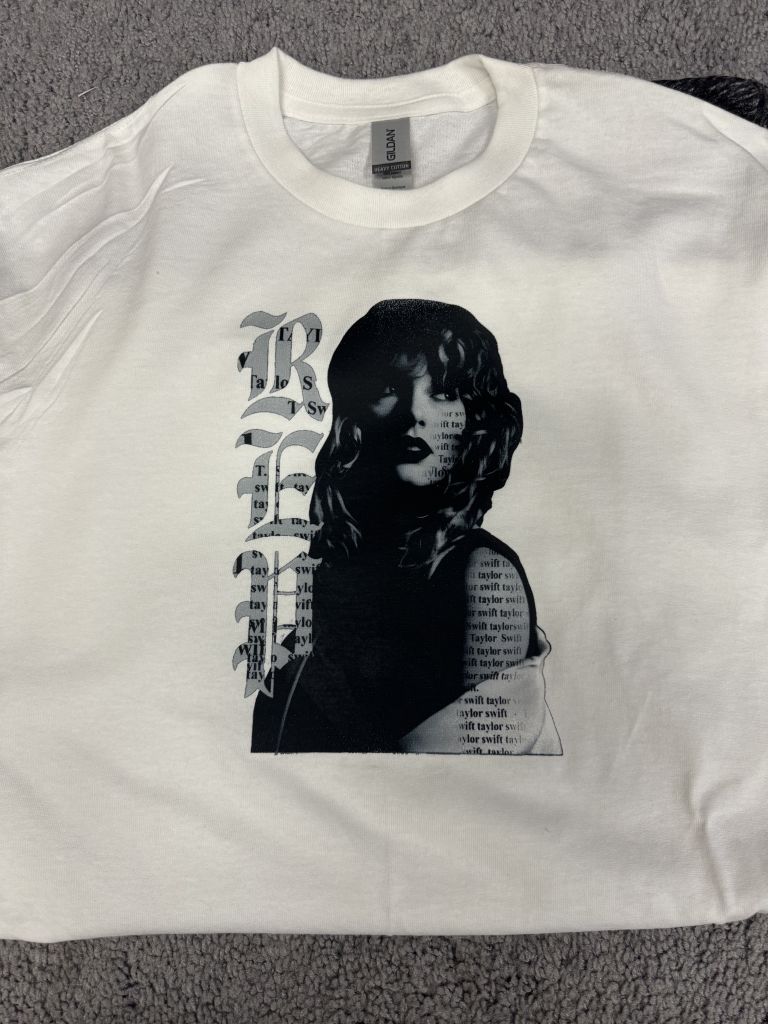

1. DTF Printing

What It Is:

Direct-to-Film (DTF) printing is a relatively new technology where designs are printed onto a special film and then transferred onto fabric using heat. This method is versatile and can be used on a wide variety of fabric types, including cotton, polyester, and blends.

Advantages:

- Versatility: DTF printing can be applied to almost any type of fabric, making it suitable for a wide range of products, from t-shirts to tote bags to caps.

- High Detail and Color Range: DTF printing excels at producing highly detailed designs with a wide range of colors. It can reproduce complex images, including gradients, shading, and even photographs.

- Durability: The prints are durable and resistant to cracking, peeling, and fading over time, ensuring the longevity of the design.

- Soft Hand Feel: DTF prints integrate well with the fabric, resulting in a soft, flexible finish that doesn’t feel heavy or stiff on the garment.

- Cost-Effective for Large Orders: DTF is efficient for large production runs, as it reduces the labor and time associated with more traditional printing methods like screen printing or vinyl cutting.

Disadvantages:

- Initial Setup Costs: DTF printing requires specialized equipment and materials, which can be a barrier for small businesses or hobbyists.

- Maintenance: The printers and heat presses used in DTF require regular maintenance to ensure consistent quality and prevent issues such as clogging or misalignment.

- Higher Costs for Small Orders: For smaller batches, DTF can be more expensive than simpler methods like vinyl or screen printing due to the cost of setup and materials.

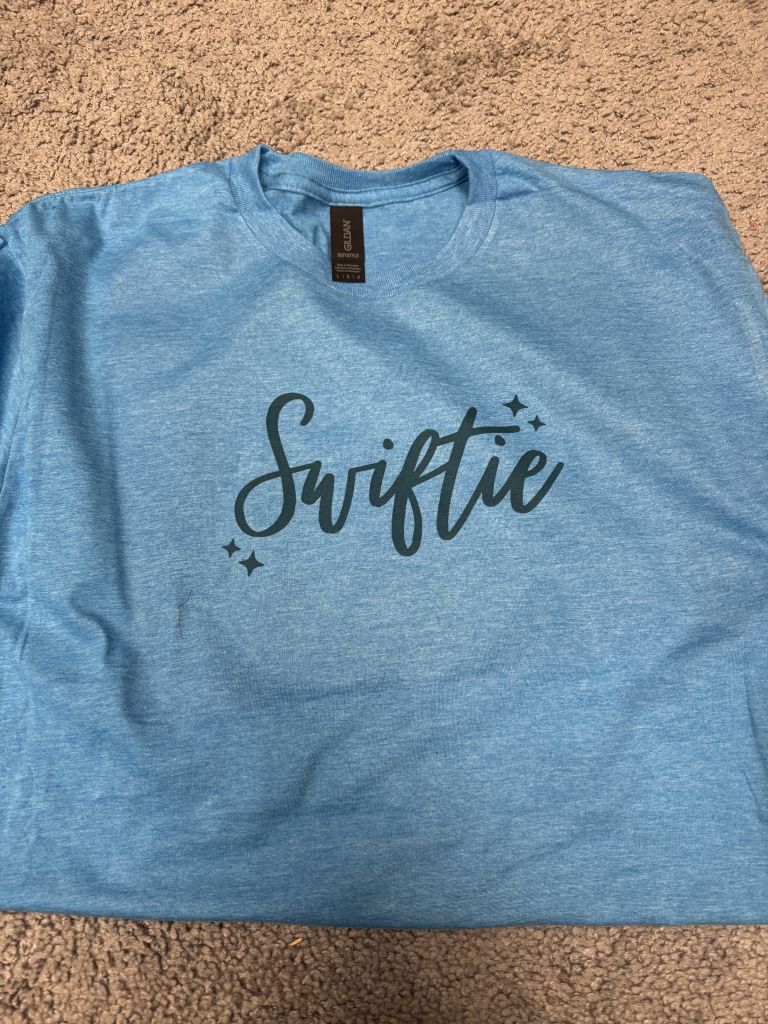

2. Sublimation Printing

What It Is:

Sublimation printing is a process where designs are printed onto a special paper using sublimation ink and then transferred onto polyester fabrics or coated items using heat. The ink turns into gas under heat and bonds with the fabric, creating a permanent, vivid print.

Advantages:

- Photorealistic Quality: Sublimation printing produces vibrant, full-color prints with photographic quality. It can handle intricate details, gradients, and shading exceptionally well.

- Soft Hand Feel: Since the ink is infused directly into the fabric, sublimation prints do not add any extra texture or weight. The result is a soft, smooth finish that feels just like the fabric itself.

- Long-Lasting Prints: Sublimation prints are highly durable and resistant to fading, cracking, or peeling. The design becomes part of the fabric, ensuring that it lasts as long as the garment itself.

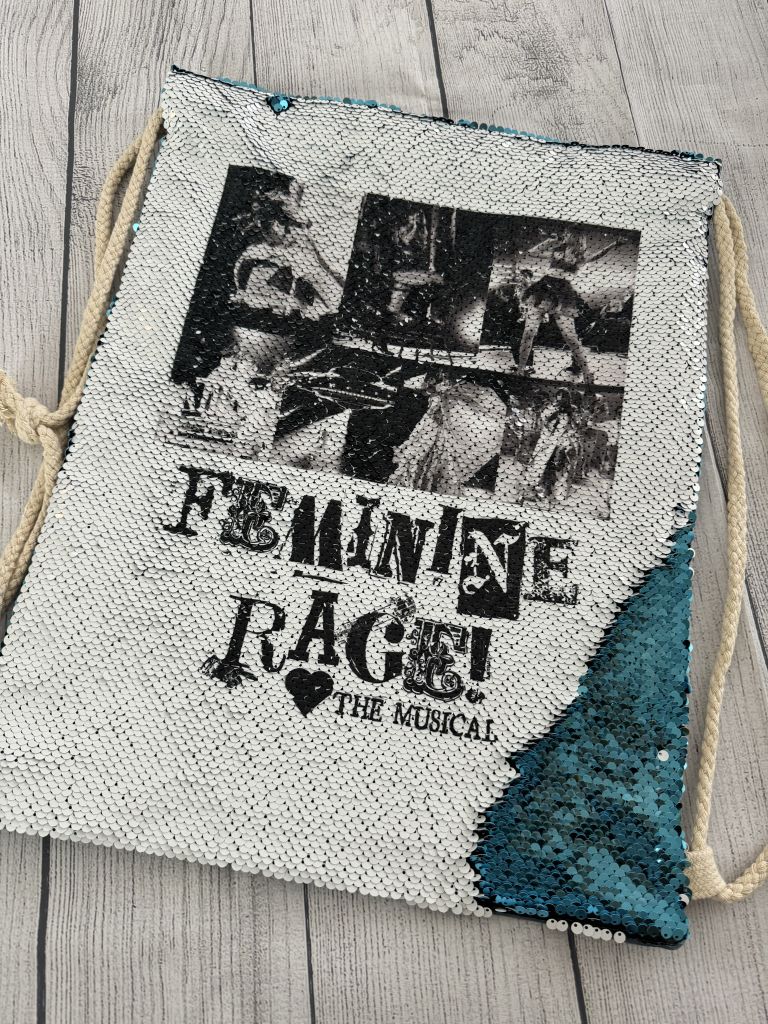

- Versatility Beyond Textiles: Sublimation is not limited to fabrics; it can also be used on a variety of coated items such as mugs, phone cases, and other promotional products.

Disadvantages:

- Material Limitations: Sublimation printing is only effective on polyester fabrics and light-colored substrates. It doesn’t work well on cotton or dark-colored fabrics, which limits its application.

- Color Restrictions: While sublimation is excellent for vibrant colors, it is less effective on dark-colored fabrics, where the colors may not appear as vibrant or may not show up at all.

- Cost for Small Orders: Sublimation can be more costly for smaller runs due to the specialized equipment and materials required.

3. Choosing the Right Method

The choice between DTF and Sublimation Printing depends largely on the specific needs and goals of your project:

- Choose DTF Printing if: You need a versatile solution that works on a variety of fabrics, including cotton, polyester, and blends. DTF is ideal for producing highly detailed, full-color designs with durability and flexibility.

- Opt for Sublimation Printing if: Your project involves polyester fabrics or coated items, and you require high-quality, vibrant, and photorealistic prints. Sublimation is the best choice for achieving soft, permanent prints on polyester.

Conclusion

DTF printing and sublimation printing are both powerful tools in the custom printing industry, each with its unique strengths. DTF is versatile and works on a wide range of materials, making it ideal for varied projects, while sublimation is perfect for achieving high-quality, permanent prints on polyester fabrics and promotional items. By understanding the differences between these two methods, you can make an informed decision that ensures the success of your custom printing projects.